A Centuries Old Craft

France is traditionally thought of as the croissant’s country of origin, but it’s in Austria where it actually began. There are many tales, but legend tells us that the first incarnation was a sweet bread called kipfel, baked initially in 1689 in a crescent shape (referring to the Turkish flag) to commemorate Vienna’s victory against the Ottoman army that had been besieging the city. In the late 18th Century a French baker is credited for transforming the kipfel to delight no other than Marie Antoinette, the 14 year old Austrian Archduchess , in celebration of her wedding to the future Louis XVI, eventual King of France. He “upgraded” the kipfel with the lamination process, turning it into the flaky, buttery pastry with which the whole world has since fallen in love.

The Oven Delight Croissant’s 36 hour journey begins...

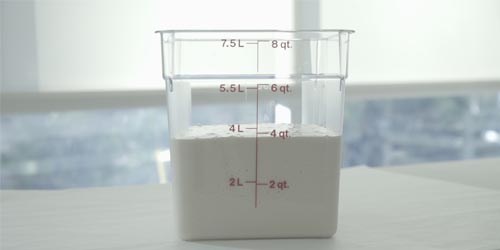

Ingredients

A few simple ingredients go into making our light, flaky croissant. It’s our understanding of these simple but complex ingredients that allows us to perfect this pastry. For example, finding the ideal flour that meets our standards requires sourcing the specific wheat, grown under the proper conditions, with the right extensibility and elasticity, is the most important part of this process. All other ingredients go through similar rigorous processes to insure our pastry is always produced with the same consistency.

Levain

(Sourdough)

We use levain, or sour, a simple ancient discovery, to give our croissants their distinct natural flavor and extend shelf life naturally. We utilize the most sophisticated fermentation process and equipment to create this traditional, natural leavening agent. Our proprietary “mother dough” is kept under strict controlled conditions and used to refresh our daily Levain.

Mixing

Once the right ingredients are selected, the mixing process starts the magic. The dough is slowly formed and stretched, while making sure it remains cool (just under 60°F). This is where our experienced dough lovers use their touch and feel to make sure every batch is perfectly mixed. As automated and efficient as we are, this is one step where the expert human touch cannot be replaced.

Fermentation

It is said that time is money. That’s not how we feel. For us and our process, time is flavor. Just like a good wine, a good dough needs time to ferment; to mature; to develop a deep balanced flavor; and to be ready to stretch and create delicate layers. In our dedicated, controlled conditions fermentation rooms, our dough is kept, nurtured, and never rushed.

Lamination

Once the dough has fully relaxed and the flavor has developed, it is released out of the resting dough troughs; stretched; and married with butter and/or margarine. Lamination, the repetitive process of folding and layering dough, is how the croissant’s thin layers are created. This is the most critical part of the process, and where we excel. The dough and environment conditions have to be under perfect control. Combining dough and fat can be very challenging, but when done right it’s a match made in heaven.

Resting

Lamination is not a one step process. All the layers are created in stages. In between each stage, the dough must be allowed to rest and cool, before it is stretched and layered again and again. In our bakery, no step is compromised or rushed. Our respect for the dough is from beginning to end and patience is a key ingredient.

Make-up

The carefully layered dough is now ready to be cut into triangles, stretched, and rolled to form at least 4 overlapping turns. This is where a piece of dough becomes a croissant, finally hand-shaped into the iconic crescent shape. But care is still of utmost importance, to maintain the integrity of the dough and not damage the thin layers that have been built over the last few hours.

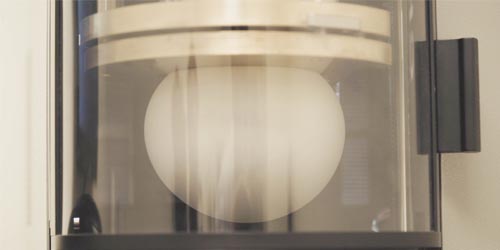

Proofing

Proofing is the critical step where a croissant almost triples in size before it is baked. Under the right heat and humidity conditions, the Levain and the yeast go to work, using energy from the sugar and starch to lighten and rise this delicate pastry. It becomes tender, light and just a little bouncy, waiting for its turn to bake.

Baking

Baking tray after tray make their way into our customized state-of-the-art tunnel ovens. The heat causes the butter or margarine to release their moisture and produce enough steam to separate the dough layers, forming webs of pastry and a golden, flaky exterior. The croissant is now ready to be enjoyed.

Cooling

Not yet! A hot croissant is good, but not as good as a properly cooled one. This is why we designed and built cooling towers where the croissants travel for almost an hour before they are ready to be eaten or packed.

Packaging

At 80°F or below, the croissant is now ready to be wrapped to conserve its freshness and flavor. At this point, our quality control and sanitary requirements are very stringent, and as the cooled croissants are conveyed to our packaging room, a set of customized robot arms with human-like, precise fingers gently grab the pastries one by one and place them into our wrappers.

The croissant’s journey is now complete, but our job is not.

We are relentless in trying to improve every part of this process every week to offer our customers the most authentic wrapped croissant.